| Company | Product | Contact | Back |

|---|

EPS 1/8 broken classified coalition prototypeHarmonized System:8474209000

EPS-1/8 crushing and cutting joint prototype is a scientific and technological product developed by our factory in recent years. The machine overcomes the defects of the original product, such as easy to stick, easy to block and low crushing force, making it more perfect, more reliable and more truly representative. The new EPS-1/8 crushing and cutting joint prototype is made according to the international standard (ISO1988-1975 ; GB/T 474-1996 ) research and development, all indicators are up to international and national standards. It has the function of one level shrinkage for materials below medium hardness. It is widely used in electric power, coal, metallurgy, geology, building materials, chemical industry and other industries. This equipment is mainly used for coal and other raw materials, the preparation of the sample blocks for crushing and screening and complete classified three working system, especially suitable for large laboratory use.

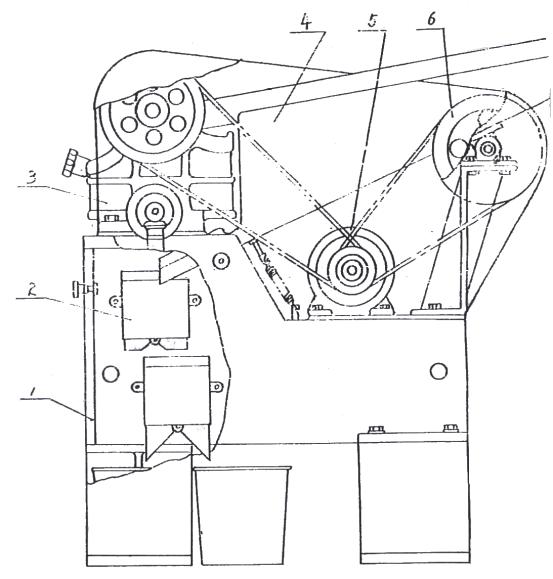

Equipment Structure and Working Principle EPS-1/8 fully sealed jaw crushing and shrinking machine is composed of motor, jaw crushing assembly, shrinking subsystem, hopper and transmission mechanism. Precautions for device installation When the equipment arrives at the designated place as required by the user, it should be unpacked and inspected in time to eliminate possible parts looseness during transportation, read the operation manual, and install, use, maintain and maintain the equipment in strict accordance with the requirements in the operation manual. 1. the equipment must be installed on the level of concrete, and between the foundation and the equipment base pad with hard hibiscus or other cushioning materials, in order to reduce vibration and noise. 2. the equipment uses 380V power supply, installation and use must be safe grounding. 3.The rotation direction of the motor must be consistent with the rotation direction on the equipment mark. Equipment Use and Maintenance: Tips before enabling: 1. Check whether the transmission parts of the equipment are flexible and all fasteners are securely fastened. Equipment usage instructions: 1. the machine is started and stable, can be in accordance with the technical parameters (feed maximum particle: ≤100mm) requirements. Equipment maintenance and maintenance: 1. Check regularly whether the fasteners of all parts of the equipment are loose. (3 months) Equipment vulnerable parts and name 1. Hammer 2. Ring shaft 3. Bearing (8006309) 4. B triangle belt Safe operation specification 1. operators must be trained in safety technology, and have a certain sense of safety. crusher link:XPZ200 x 75 double rollers crusher Sealed sample testing system GJ series crusher The SMP - 400 wet coal crushers PCZ series seal hammer crusher WZ - 50 type miniature system prototype Telephone: 0086-392-3313798 fax: 0086-392-2172001 Zip number : 458030 Address: He nan hebi citizens born technology development Co., LTD. |